TIM gate, VRM disaster? Possible X299 motherboard faults and Skylake-X

In recent weeks, the leaf and video forest has been quiet. Even a VRM disaster or TIM gate (hot paste instead of lot) were discussed, but if you examine closely, the G… Thermal paste instead of solder Intel’s choice of improper (but cheaper) thermal paste instead of indium-based solder contributes to the cooling issue. Discuss the shelf life now… Default Settings Outside the Box, Cheats, Heat Long before launch, motherboard manufacturers made the first critique.

A typical all-in-one compact water cooler has dozens… We hold motherboard makers accountable. Blaming the imminent heat inferno just on Intel and the CPU cranked to its maximum limit would have been too short-sighted.

Noise across all media has been scarce in recent weeks. There was even discussion of a VRM disaster or TIM gate (thermal paste instead of solder), but the whole thing is just a long causal chain that starts with a hot-headed CPU. In theory, there are three. We try to make it simple, so one after another.

(1) Skylake-X is hardly coolable out-of-the-box in typical use due to excessive power consumption and thermal paste that limits optimal heat dissipation.

(2) The average user has little overclocking room, and many motherboards limit the CPU owing to design issues like insufficient external voltage converter cooling. Extreme overclockers barely work with modern hardware.

Usually, too much rhetoric is added, which doesn’t do credit to the potential purchasers’ difficulties.

Test setup and measurements

We’ll acquire a simpler Socket 2066 motherboard, make a vertical benchtable, and test (or not). We’ll look at the sensor values and origins of the respective areas, and we’ll use the infrared thermal imaging camera to test the board’s heating around the socket and voltage converter for plausibility.

We can also record the heating process in time-lapse videos. We also want to know if motherboard hotspots or heat transfer damage other components.

For safe sensor readings and smooth test setup operation, we use the newest motherboard BIOS and HWinfo in the latest beta version from v5.53-3190 (click on beta version while downloading!). We fixed or deepened certain features after a deeper inspection, manufacturer check, and community suggestions.

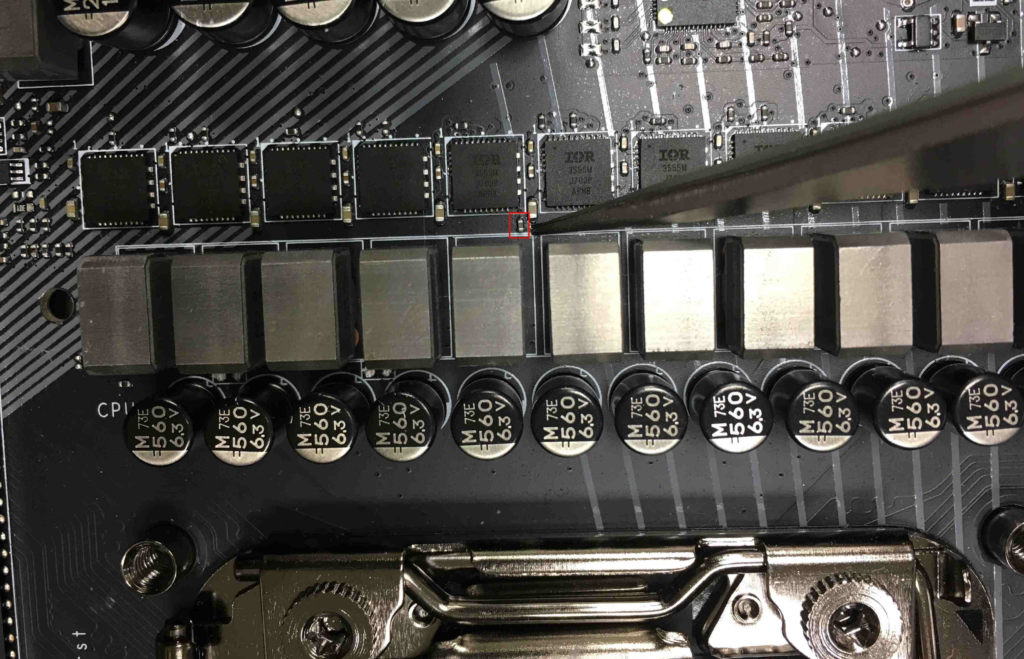

The board’s CPU power supply has 5 1 phases controlled by an International Rectifier IR35201. This multi-phase buck controller supports Intel VR12 and evidently VR13. The so-called doubling allows two circuits per phase with five phases, relieving the individual VRMs and equalising hotspots in area. This chip’s voltages and currents will be discussed later.

Each control circuit uses one International Rectifier IR3555 voltage converter. These highly integrated power stage chips include gate drivers, high- and low-side synchronous MOSFETs, and the Schottky diode. Unlike other MOSFETs, they have analogue temperature sensors. How else can you accurately measure these voltage converters’ temperatures without an IR camera?

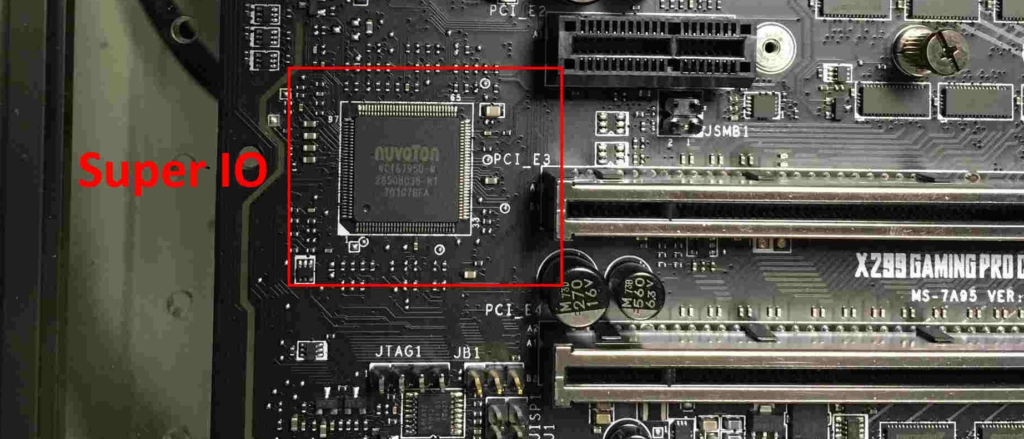

MSI employs the Nuvoton NC6795D as a Super IO chip on the tested motherboard to record and provide sensor information. With a central thermistor between the power stage chips, the voltage converters’ temperature is likewise measured. Thus, we choose the back measuring point below this thermistor for our video acquisition.

The coils and capacitors of these voltage converter circuits and the board temperatures up to the CPU are also checked.

Sudden shutdown and downclocking

To better comprehend the future testing and the concerns that were often addressed too polemically in forums, we must realise that motherboard makers use safety devices. The Skylake-X is clocked down to 1.2 GHz at exactly 105°C at the thermistor (HWinfo under line MOS, Nuvoton NCT6795D) by our test board until the temperature drops below 90°C. Only then does it reach full velocity.

This makes sense since the flash point for the PCB material (FR4) is much higher, but the maximum continuous operating temperature is only between 95 and 105°C to avoid dry-out, bending, and conductor path hairline cracks in multilayer PCBs. This is good because graphics card makers normally have more (unnecessarily) nerve in this area.

In Intel’s Extreme Tuning Utility (XTU), this downclocking termed Thermal Throttling: Yellow, yes. What about Motherboard VR throttling status indicators? We must also give a little addendum regarding HWInfo values. It is less well known that the IR35201 also measures temperature. These results for VR T1 and VR T2 are much higher and appear to contradict the external sensor.

As usual, only the controller chip temperature was output. This would be equivalent to voltage converter temperatures VRM1 and VRM2 on graphics cards with PWM controllers (AMD cards commonly utilised them) in various tools. Usually, the chip measured itself there. However, with IR35201 and IR3555, it can be presumed that the IR3555’s voltage values and temperature inside are also utilised.

Before the XTU yellow warns of motherboard VR throttling, these values are limited to 125°C and the CPU is clocked to 1.2 GHz. Because voltages could run outside specifications and damage hardware above 135°C, the motherboard is turned down without notice.

CPUs also protect themselves. Multiple integrated digital temperature sensors (DTS) determine the computing core and package temperatures. The precision of these calculations rises with temperature. Below 40°C, it’s irrelevant, but from 80°C, it’s accurate. We can also see that core and package temperatures can cause clock throttling.

The power loss of the IVR the CPU’s voltage converters that provide partial voltages is also included in package temperatures. With strong overclocking and manual voltage increase, unanticipated limit overruns might occur quickly, which not all tools can detect. So the CPU throttles without the user knowing why. The IVR will be discussed shortly.

[…] Motherboards: ASUS ROG Maximus Z790 Formula & ROG Maximus Z790 APEX Encore Pictured […]

[…] the release of Intel Skylake (6th Gen) and Braswell, ASRock Industrial has provided tiny boards and mini-PCs to the industrial systems […]